We have some useful tips for you about metal roofing installation. If you have any problems with roofing installation, or need help with the technical aspects of laying your metal roofing, ask us for any advice you need. We’ll be happy to provide any assistance you need.

Roofing Installation Basics

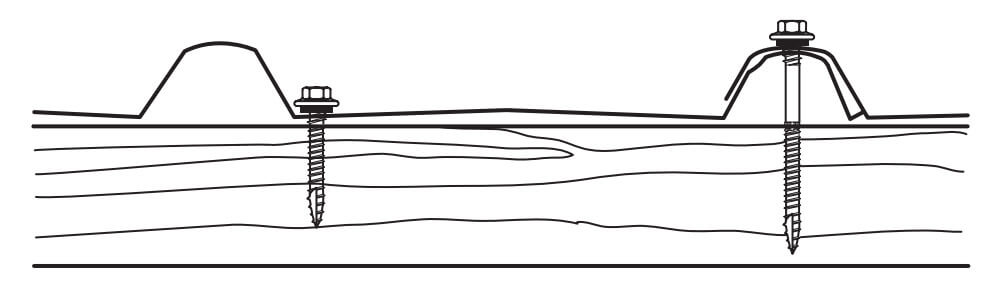

Pierce Fixing and Concealed Fixing

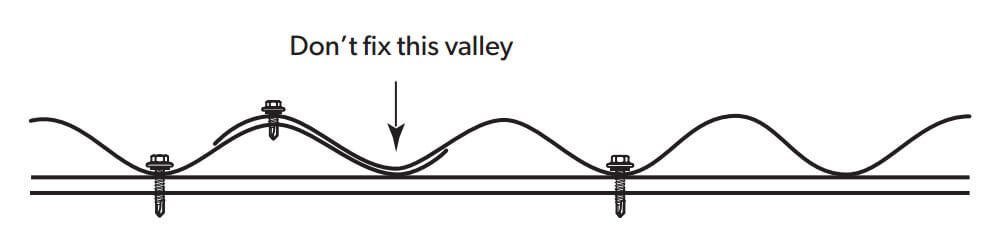

Pierce-fixing uses fasteners to attach the sheet to the roof frame. Screws should be fixed perpendicular to the sheeting or cladding in the middle of the rib, and always at the top of the crest for maximum water tightness. Screws can be fixed through the pan/ valley or crest for walling applications.

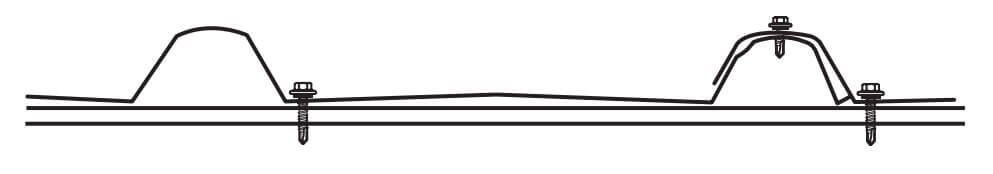

Concealed fixing uses fasteners and clips and this method means that the screws will be hidden underneath the exterior of the roof sheets. Clips are affixed using double sided facings and at regular intervals along the sheeting according to site requirements.

Please note that these two types of fixing are used for different types of metal roofing. If you’re not sure which is best for your type of roofing, ask us.

Before you start

Prior to carrying out any work on your roof, be sure to check that:

- Supports are evenly laid and square on the same plane

- Minimum roof slope adheres to the minimum roof pitch for your specific profile

- Overhangs of metal roofing should conform with design specifications whilst also overhanging at an even length into guttering.

DO NOT lay further sheets if any sheeting is uneven or crooked (This will save you a lot of remedial work, which can be very hard work indeed).

Orient sheets before lifting

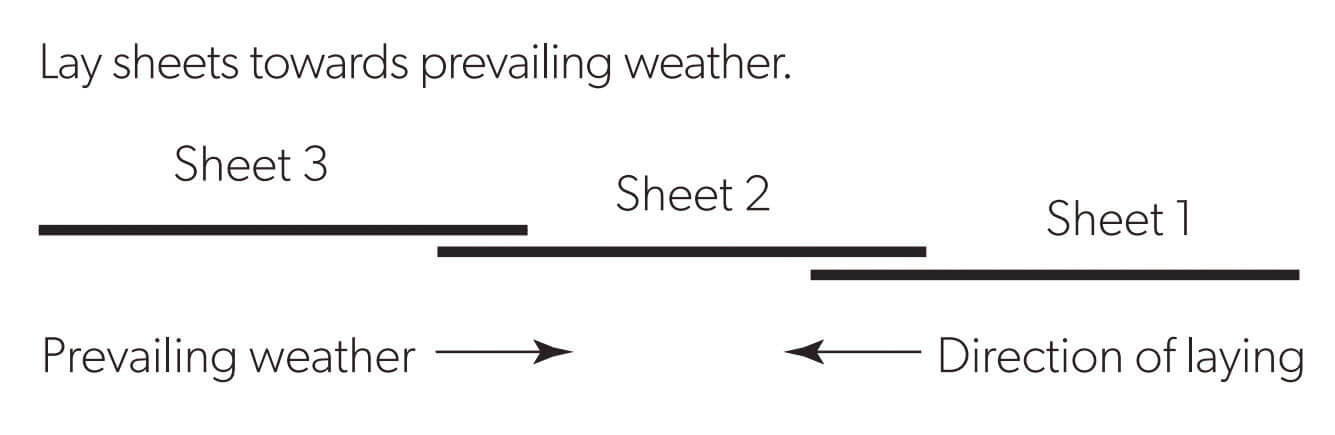

For best weatherproofing, begin installing your sheeting on the side opposite the prevailing wind.

Position your sheets on the ground before raising to the roof for laying. Sheets should be checked to ensure that the top side faces upwards. The overlapping sheet edges should be raised facing the direction of installation, i.e., positioned the same way as the other sheets.

DO NOT place sheeting in a position where it isn’t fully supported, to avoid bending.

Laying the first sheet of roofing

Make absolutely sure the first sheet laid is properly positioned.

Ensure that:

- Sheeting is properly aligned

- Both ends are properly positioned in accordance with the roof plan.

Proceed to the next sheet only when you’re sure your sheeting is 100% accurately laid.

Position your next sheets

After fixing the first sheet in position, align the following sheets using:

- The long edge of the previous sheet; and

- A measurement from the end of the sheet to the fascia or purlin at the gutter.

It is important that you keep the gutter-end of all sheets in a straight line. Fix the sheet by either:

- Fixing each sheet completely, before laying the next; or

- Fix the sheet sufficiently to ensure it can’t move, complete laying all sheets, then return to place all the intermediate fasteners later.

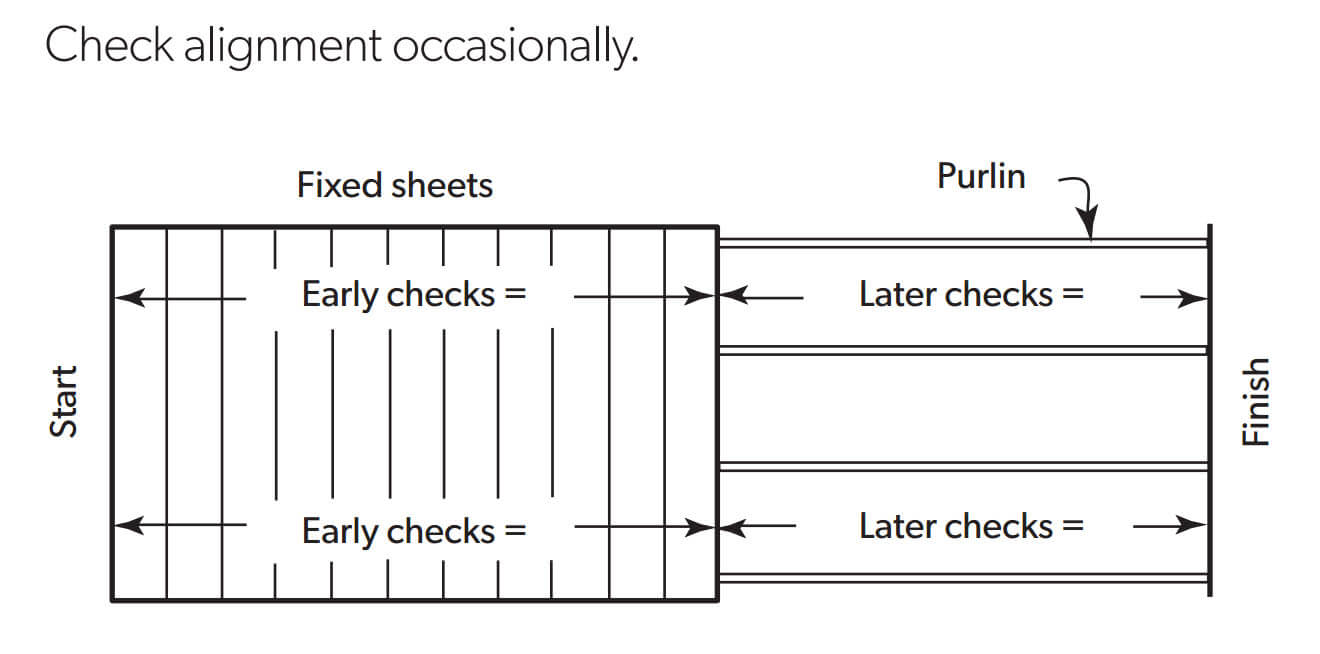

Check roofing alignment regularly

Be sure to keep an eye on each metal roofing sheet to ensure they are properly aligned in relation to the first sheet.

Take two measurements across the wide face of the sheeting and compare. They should be the same.

Errors and alignment problems?

At intervals during the job, perform a similar check. Measure from the finishing line. The last sheet should be aligned in direct parallel with the end of the roof. If sheeting is slightly misaligned, lay subsequent sheets accordingly to correct the alignment:

- Properly align and fix the sheet.

- Fix the opposite edge of the sheeting, with fasteners or clips nearer or farther from the position they would be on the correct alignment. Progressively fix alignment so sheets are brought back in to the proper position.

Working with side-laps and pierce-fixed sheets

To avoid moisture entering laps by water action, metal sheets are slightly modified to manage this problem. All profiles are designed for only one rib to be overlapped to ensure the water tightness. Sheets must be properly affixed according to the type of sheeting you’re using.

Crest fixing and side lapping

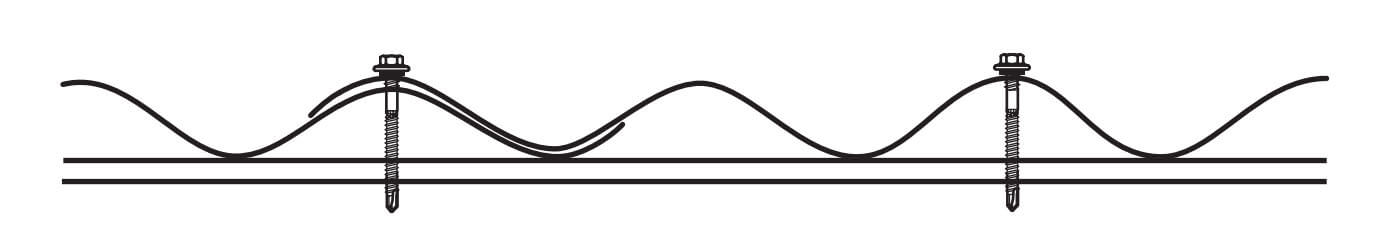

Corrugated Roof Sheets

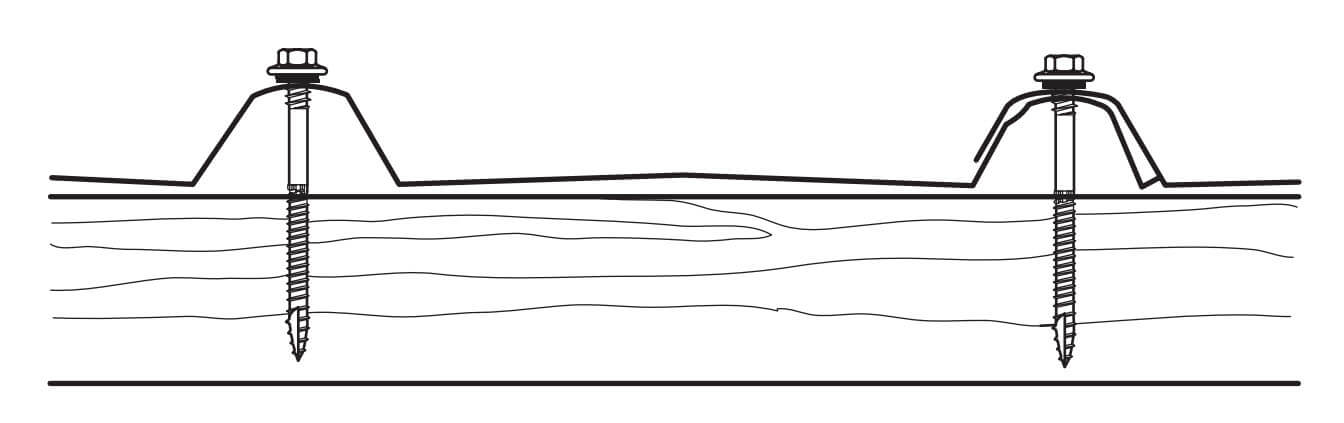

Five Rib Roof Sheets

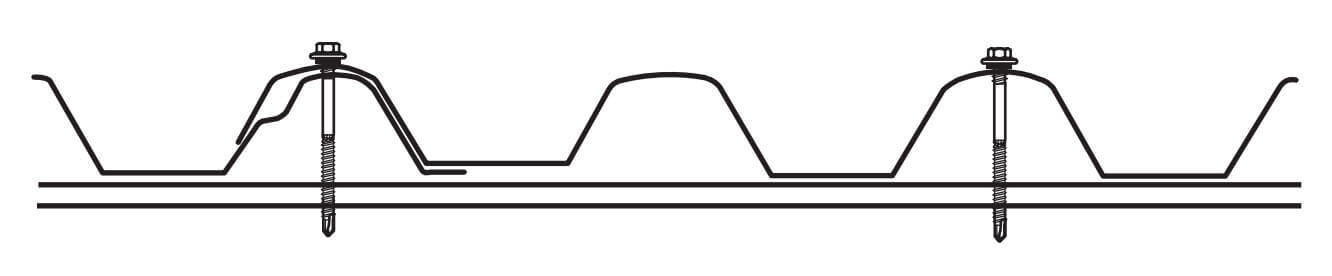

Span Roofing Roof Sheets

Place the first sheet and following sheets with their side-lap fitting closely over the sheet laid before it. Ensure that sheets are fitting well at each stage of laying until the final end of the sheet has been laid.

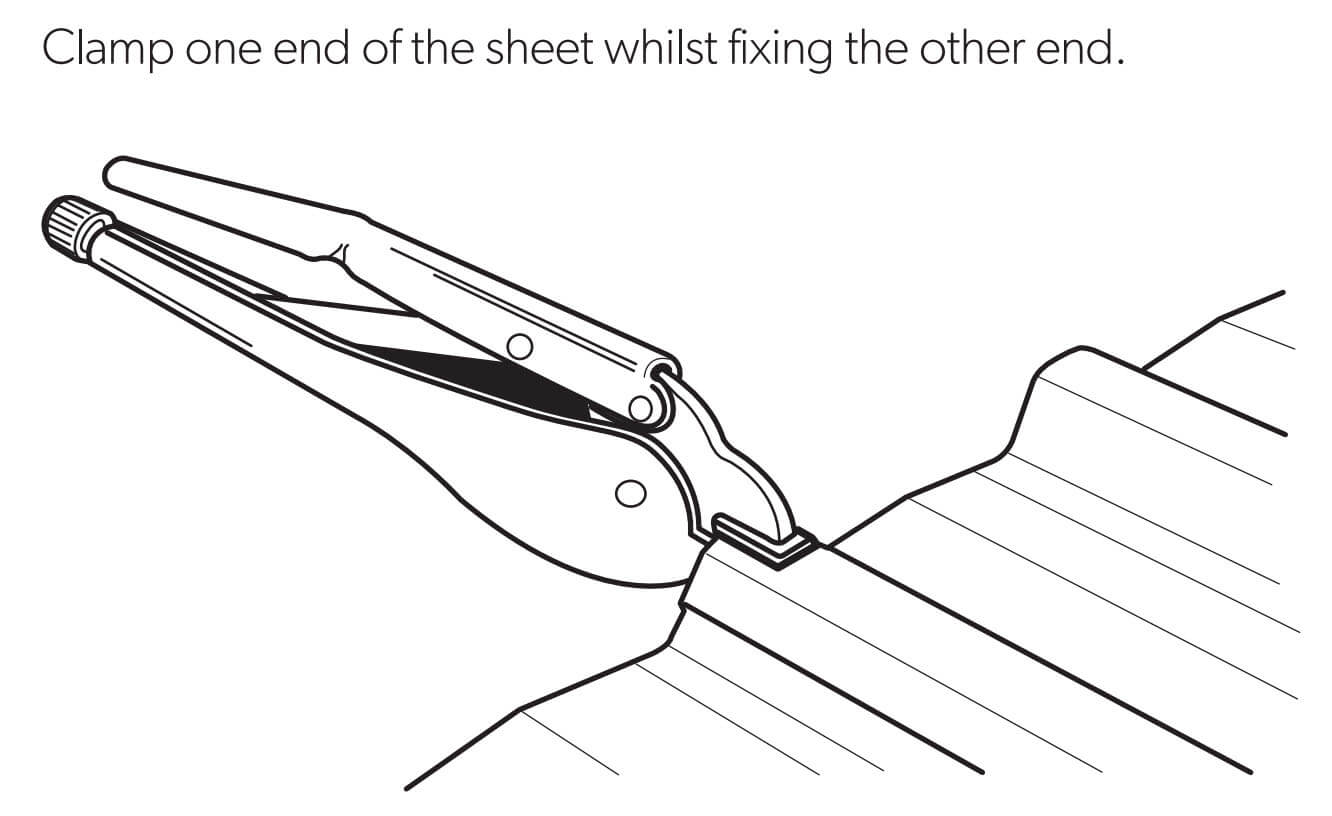

This is actually pretty easy:

- Position the bottom end of the sheet by measuring from the end of the sheet to the fascia or purlin;

- Secure the sheeting with vice grips/clamp;

- The upper end of the sheet: should meet the side-lap very closely; check positioning, and fasten the sheet when you’re happy with its position.

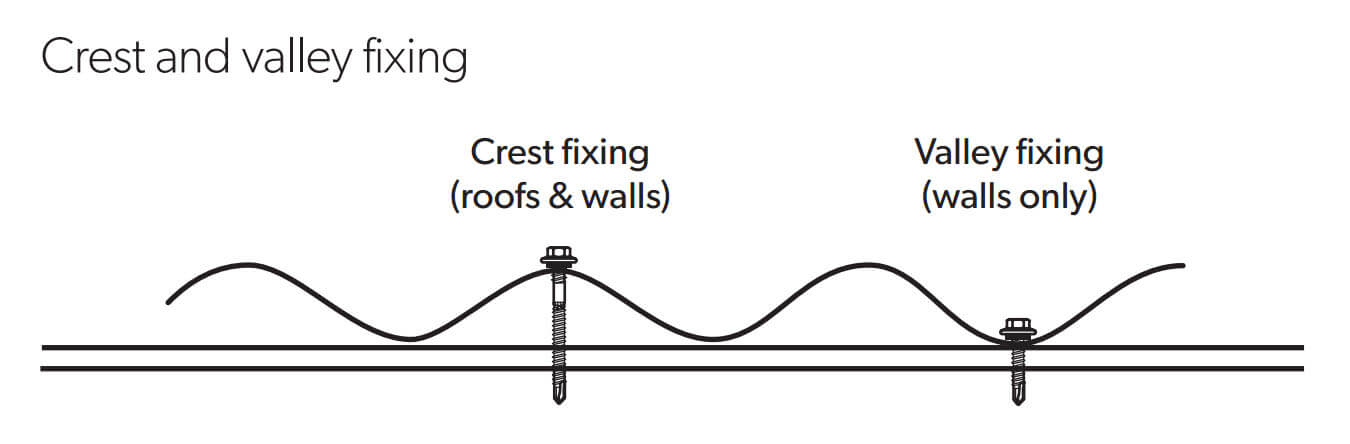

Crest fixing

Pierce fixing on crests is always recommended when using the following roof profiles for roofing applications:

- Corrugated roofing

- Curving Quality

- Five Rib roofing

- Span roofing

Crest fixing may also be used on the above products when these are used for walling applications, however valley fixing is more common for walling.

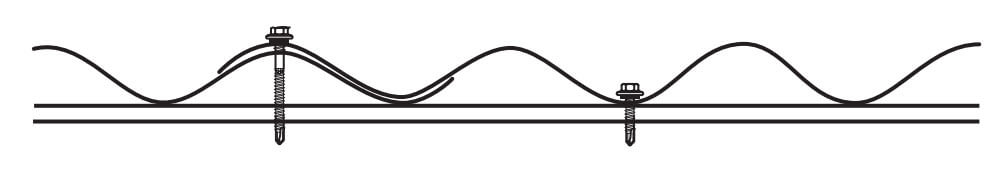

Valley fixing

Pierce fixing on valleys is recommended when using the following profiles for walling applications:

- Corrugated roofing

- Curving Quality

- Five Rib roofing

- Span roofing

- Mini Corrugated

- Mini Rib

Fasteners are used placed in the valleys of wall cladding due to the following:

- They are less visible and don’t break up the aesthetic lines of the sheets

- There is no risk of the profile being deformed as it will rest flat against its support

- Water penetration will not occur

Although when valley fixing you will always require a side-lap fastener in all laps at each support. It works out to be more economical to with labour, time and with the cost of fasteners to use a crest fastener at each side-lap in place of the lap fastener and adjacent valley fastener.

Typical valley fixing for walling only and side-lapping

Corrugated to steel support

Five Rib to steel support

Alternative valley/pan fixing with crest fixing at side-laps for walling only

Corrugated to steel support

Five Rib to steel support