Quiklok 700 benefits from a strong, clean finish without any visible fixings utilising a revolutionary concealed clip. It is ideal for long length roofing in both domestic and commercial applications, due to its allowance for thermal expansion and contraction.

The unique design of Quiklok 700 including the high ribs and deep pans mean that it is suitable for areas with high rainfall whilst allowing for a roof pitch as low as 1°. This decking system allows for an unrivalled wind load performance and uniform bird proofing. Quiklok 700 is available in a huge range of Colorbond® colours as well as Zincalume®.

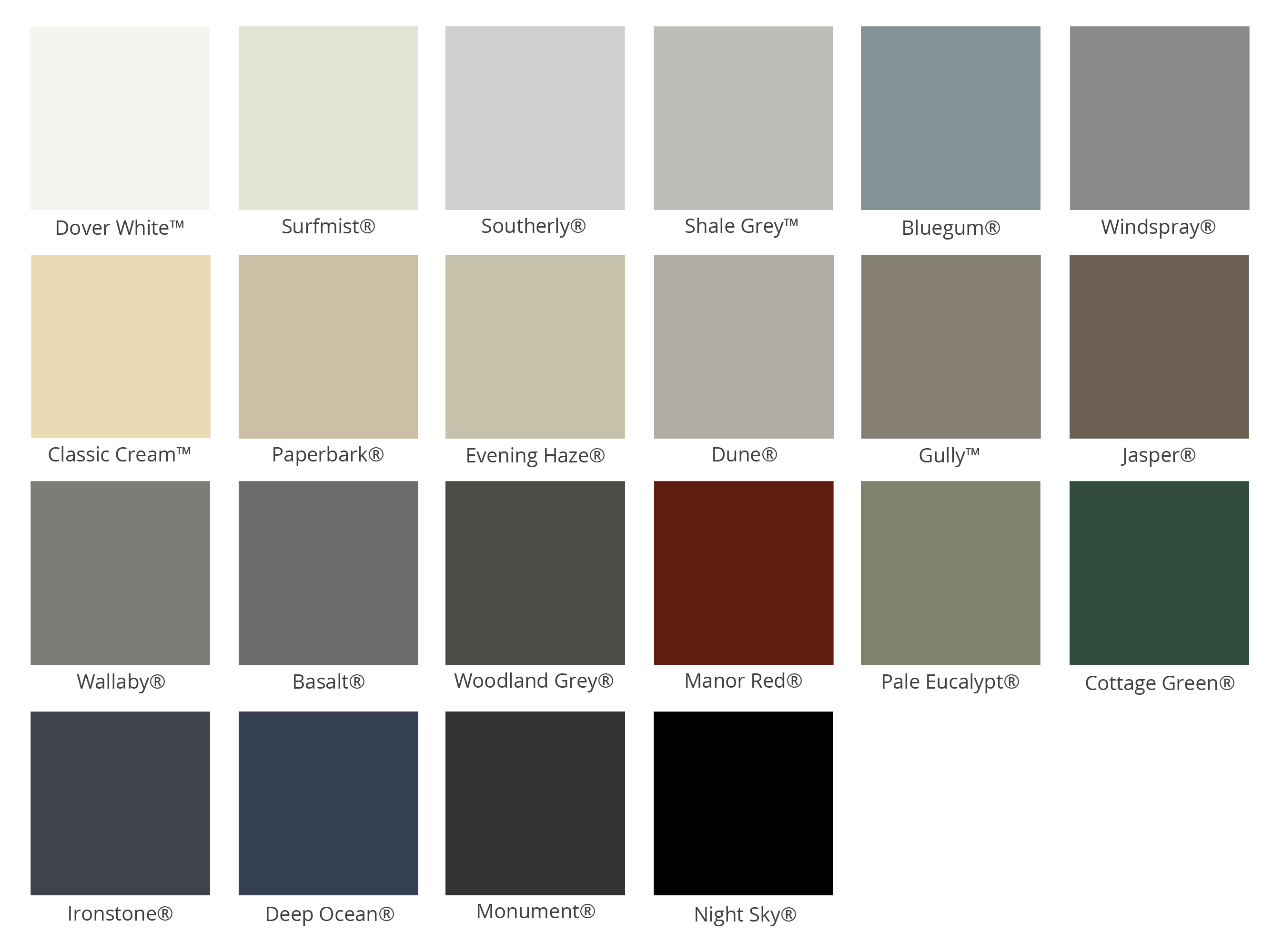

Available Colours

The Colorbond® steel colour swatches above have been reproduced to represent actual product colours as accurately as possible. However, we recommend checking your chosen colour against an actual sample of the product before purchasing, as varying light conditions, different screens and limitations of the printing process may affect colour tones.

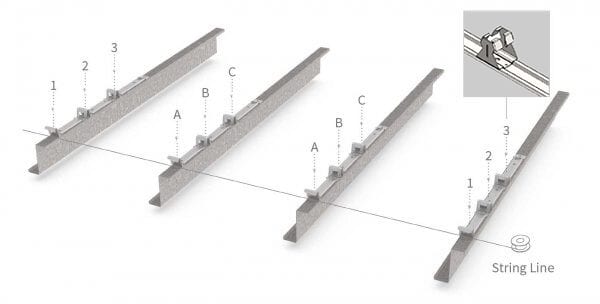

Concealed Clip

The most important feature of Quiklok 700 is the single piece concealed clip. Its innovative design ensures maximum performance of the roofing, superior spanning and ease of installation. It is suitable for a variety of industrial and commercial uses, and can be used where a low roof pitch is required and security is important. Buildings such as shopping centres, hospitals, industrial storage, factories and warehouses lend themselves to this style of roofing for its strong, reliable, no fuss application.

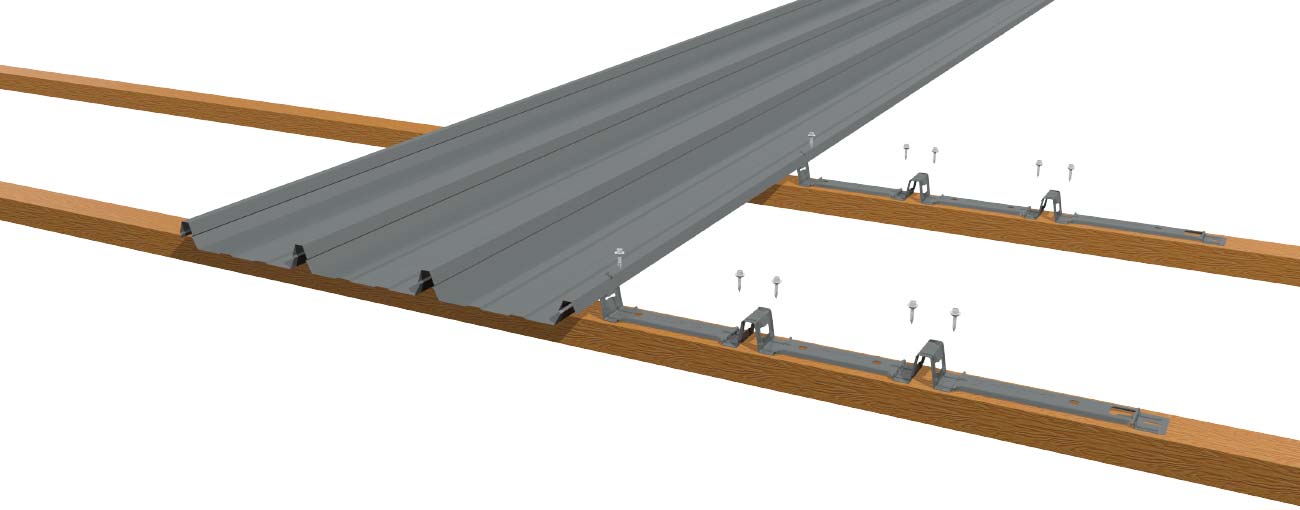

• Specially designed single piece galvanised steel roof clip eliminates the possibility of mechanical failure

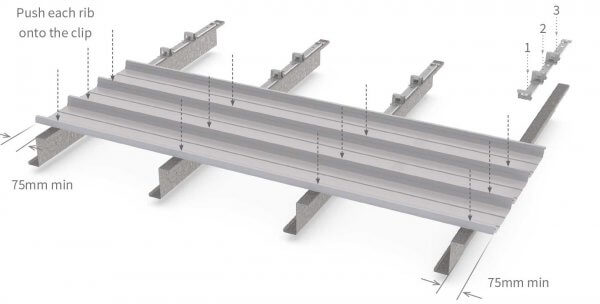

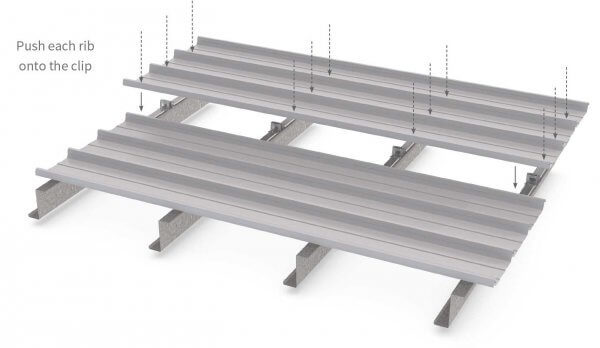

• The clip is simply fastened onto the purlin and the roof deck locks straight onto the clip for fast and easy installation

• The secure locking action ensures the deck is water tight and protects against entry

• All fasteners are covered by the deck helping to minimise fixing corrosion

• Specially designed recesses for fastening avoid denting the roof sheet.

• Allows for bracket adjustment to accommodate out of square buildings or installer requirements.

Fastener Selection

12 x 40 T17

To be used for fixing the conceal clip into timber

12 x 30 SDS

To be used for fixing the conceal clip into steel